PROCAST PFP Casting Systems

Jurunature Sdn Bhd manufactures it’s our proprietary PROCAST PFP CASTING systems. This are removable PFP casting for items such as valves and flanges and any equipment that requires inspection and maintenance.

As the castings are fully removable, and reusable, maintenance and inspection of the items can be carried out with little inconvenience. Where wet application is used, PFP cast access boxes can be fitted to pipes, vessel body and other structure, to allow inspection for under insulation corrosion etc.

The pictures demonstrate the process for the Procast PFP castings for the Helang and Talisman project. These castings are individually designed after site stringing, to determine size and shape requirements needed to fit local situation. When practical, foam cut-outs are used first as trial fit items for the Procast PFP castings before making the castings. The Procast PFP castings are reinforced with steel or metal mesh at the mid DFT thickness point, which extends all the way into the flanges.

|

The Talisman SDV valve and actuator system prepped for wet application. |

|

The actuator spring end after wet application. |

|

The valve body after wet application. Note, the nameplate and data plate have been left uncovered. They were later covered by removable PFP access panels. |

|

The actuator end during wet application. |

|

A selection of the PFP covered metal box castings during fabrication. |

|

Some nut covers in the foreground, and the spacer bottom flange cover sections in the background. |

|

The position indicator cover, during fabrication. |

|

The completed Talisman SDV. The wet application and all but the flange castings are completed. The flange covers were to be fitted offshore, after installation of the valve (which we later did). |

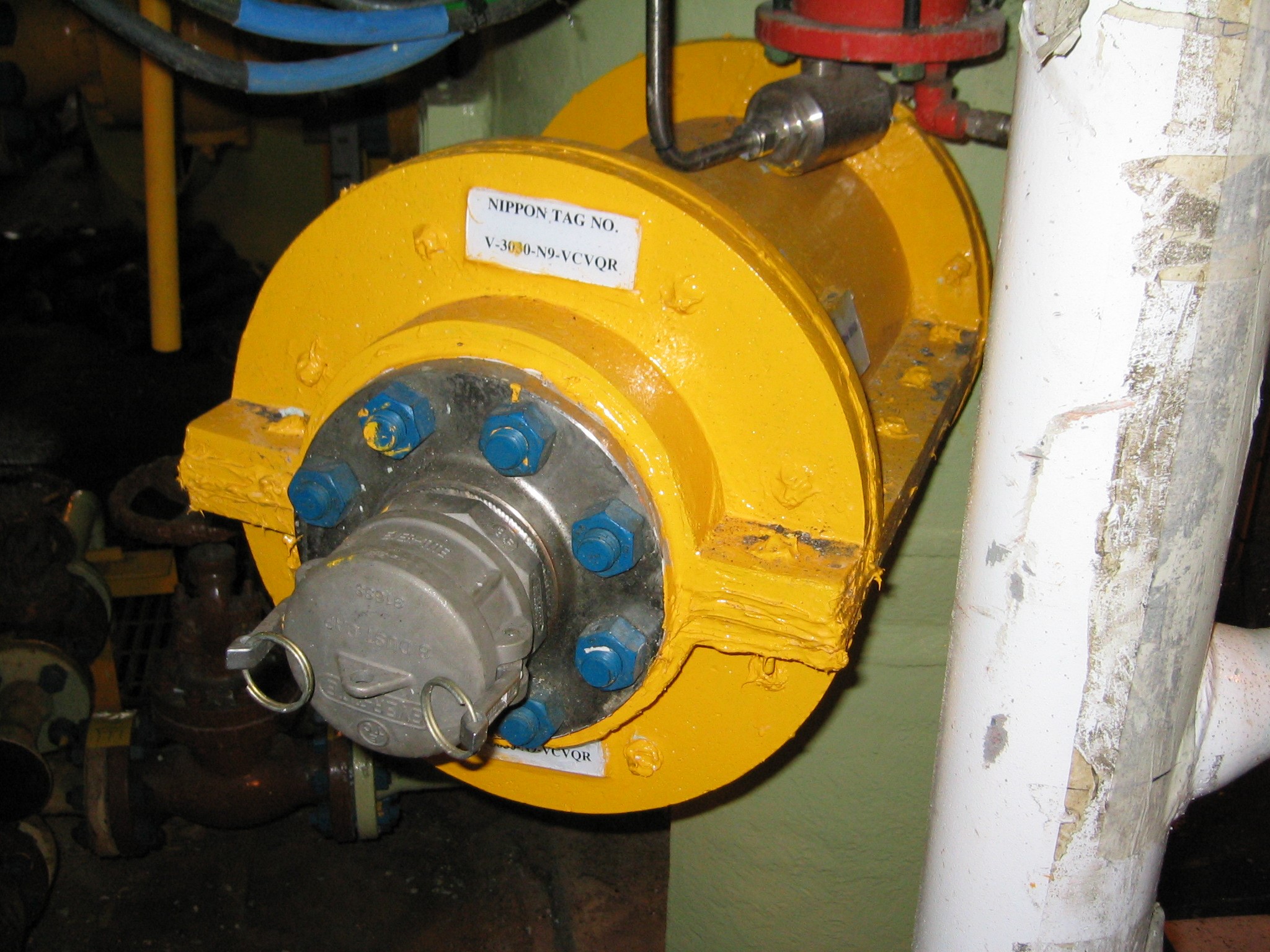

The following are the pictures showing the FULL PFP casting process used for the Nippon Oil Helang Platform project.

|

The Nippon Oil Helang Platform during construction at MMHE. |

|

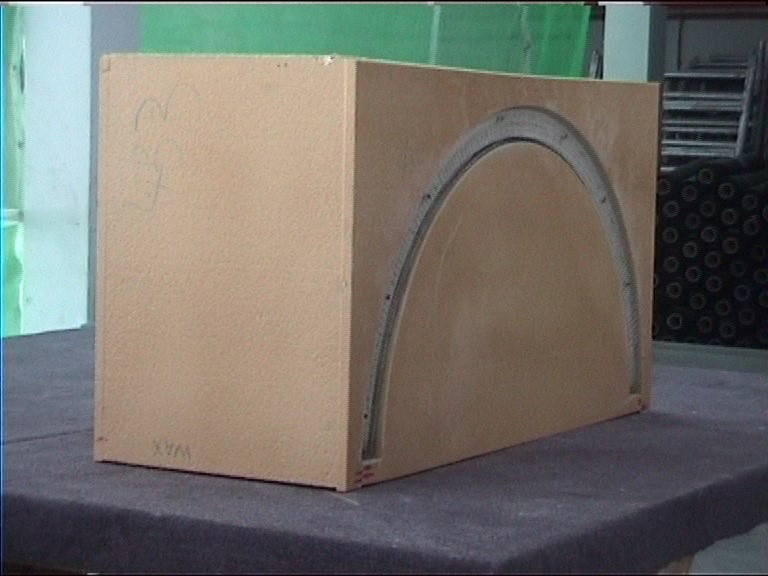

A foam cut-out for trial fitting to a flange. |

|

The trial fit foam cut-outs for the SDV actuator center section. The items have a PU coat applied to maintain form. The items shown here assembled in the factory prior to taking to site for trial fit. |

|

The trial fit of the SDV center section at site. |

|

Trial fit of the Position Indicator cut-out, on top of the actuator center section. |

|

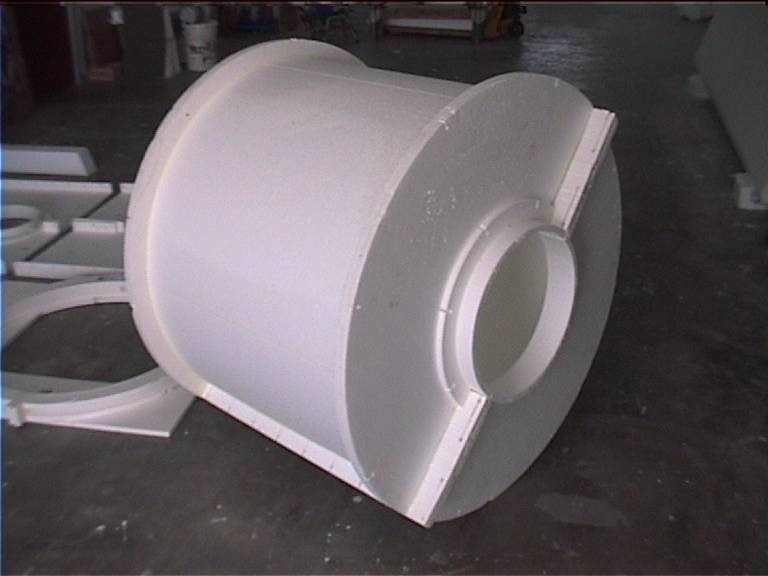

A PU coated foam mould prepared and ready for casting. |

|

The castings being removed from their moulds. |

|

A completed valve casting, fitted, sealed and painted. |

|

A valve casting sealed to the quick release connector’s flange, to allow uninterrupted access to the quick release connector. |

|

A pair of flange castings. The rear casting is fitted over a flange with spectacle blind. |

|

A 24” Manway cover fitted with the removable PFP casting. |

|

The completed 36” Main SDV, installed and fitted with its PFP castings and wet applied PFP. |

|

|

|

||

As the castings are fully removable, and reusable, maintenance and inspection of the items can be carried out with little inconvenience.

Where wet application is used, PFP cast access boxes can be fitted to pipes, vessel body and other structure, to allow inspection for under insulation corrosion etc.

The PFP material also provides insulation and blast-proofing properties.