Topside Robotic Inspection

CAPABILITIES

- Independent Robotically Inspections

- ISO 9001:2008 and VCA approved

- Certified inspectors and high-tech equipment

- Real-time followed from ground level

- Minimize downtime during shutdowns

- Safe, time efficient and cost effective

STORAGE TANK INSPECTION

Large chemical and petroleum product storage tanks can be found at chemical processing plants, refineries, and industrial locations. They are huge metal structures 150 feet in diameter and 50-60 feet tall and can easily hold more than two million gallons of gas or other hazardous liquids. Most tanks are made of steel plate that is welded together to form the structure. The material and the welds are inspected for manufacturing defects when constructed but must also be periodically inspected throughout their service life for signs of damage. The carbon steel is prone to attack by corrosion and in some circumstances cracks can form over time.

NDT personnel use visual, ultrasonic and other inspection methods to search for flaws and service-induced damage.

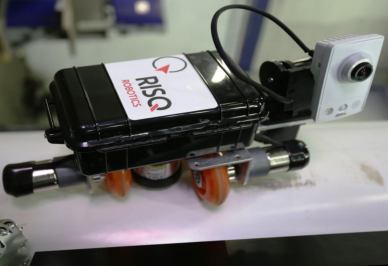

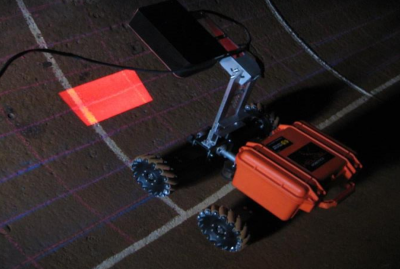

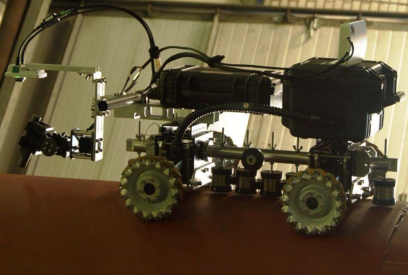

Inspections and thickness measurements of the tank walls can be made manually with the inspector in a man lift or hanging down from the top. However a much safer way to make an inspection is to use our Risq robot. Our robots can climb to the tank walls. Using remote controls, our operator guides them into positions and makes the necessary measurements with our high tech instruments.

COATING INSPECTION

Coating inspection of Risq industrial Services ensure your coating work is protecting your assets.

Whether your assets include the management of construction sites, factories, laboratories, shipyards or power plants, you need to be certain that your coating work is protecting your facility. Coatings failures mean expensive repair costs and lengthy downtime. Our coating inspection helps ensure the continued protection of your facility

WHY USE COATING INSPECTION of Risq Robotics

To ensure that coating work is fully protecting your facility, we provide comprehensive inspection of coating work, with our inspections machines we can inspect the coating work safe and ensure the clients that there will be no or minor downtime.

Our coating inspection will:

Assess coatings on ferrous-steel, stainless steel, aluminum, concrete, brick or plastic for conformity, compatibility and performance

Avoid expensive repair costs and downtime due to coating failures such as concrete decay, corrosion and loosening adhesive coats

Our coating inspection includes:

- Damage assessment and expertise

- Determination of surface roughness

- Technical specifications

- General technical assistance

- Loss assessment and repair advice

- Periodic technical inspections

- Technical coating research

- Testing of coat thickness

RISQ robotics performs independent inspections for e.g. the following industries:

- Oil, gas and chemical industries

- Power plants

- Wind farms on and offshore

- Maritime

- Defense facilities, navy